Engineering

I never studied Engineering, I more grew into it as a physicist who was looking for applied sciences. My method is to create and sketch systems from the outside to the inside, meaning from system to sub-system, to sub-sub-system, and so on.

Physics is all about systems and solving them. With user centric design, the boundaries of a system can be defined and adjusted. Everything in between is work.

In over 10 years of work expertise in a variety of fields of engineering, like Systems Engineering, Hardware Engineering, EMI Engineering, Test Engineering, Innovation Engineering, and so on, I found out that I am really bad in Software Engineering /coding. My brain is not made for that language.

I like to work in a team. It's more fun.

Here are my recent projects:

#1: Test Farming

Test- & Hardware Engineering

Scaling up Daimler‘s Software Factory

The Challenge: "Finding the error in 8 billion lines of code - every day."

Challenge

Umlaut (part of Accenture) expanded their testfarm of over 200 units from Böblingen to Berlin, where Daimler‘s Software Factor headquarter is located. The challenge was that the test units were located all over the building on the test engineers table, compared to BB, where the test units could only be accessed remotely. It was nearly impossible to maintain a standardised hardware configuration since the Test engineers like to go wild on their hardware and change it according to their individual needs. In addition, regular software updates and system fixes needed to be performed, without interrupting the user.

Solution

To maximise system availability in this special configuration, I set up a change plan containing the following 5 five key goals and took the lead in all of them.

1) Enaure a standardized and rugged hardware design of all 100 Berlin test units, that indicates visually the correct cabeling vi labels and colour coding.

2) Onboard all 400 Mbition employees with a flyer on how to use the MTTF setup correctly.

3) Implementing a JIRA-based ticket system for fast and reliable support request.

4) A stronger connection to the mothership project team in BB ensure that improvements can be implemented.

5) Implementation of an ML-based watchdog (AWX) to reduce downtime, that fixes 90% of the errors automatically.

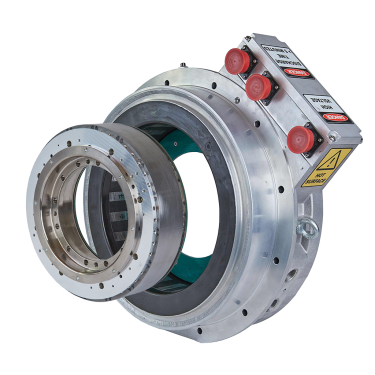

#2: Developing an electric motor

System- & Electric Engineering

Developing an electric propulsion system for the Hawkei /Thales Australia

Implementing functional safety ISO 26262 for product development (TRL-6) for the Thales Hawkei (1.2B$) electric propulsion system.

Product development in hardware and functional safety for manufacturing the electric power generation and propulsion unit for 1100 Vehicles (1.3 billion dollar project)

Leading role in the development of the electric propulsion system including power electronics for the mobility solution “Hawkei” (Thales Austria).

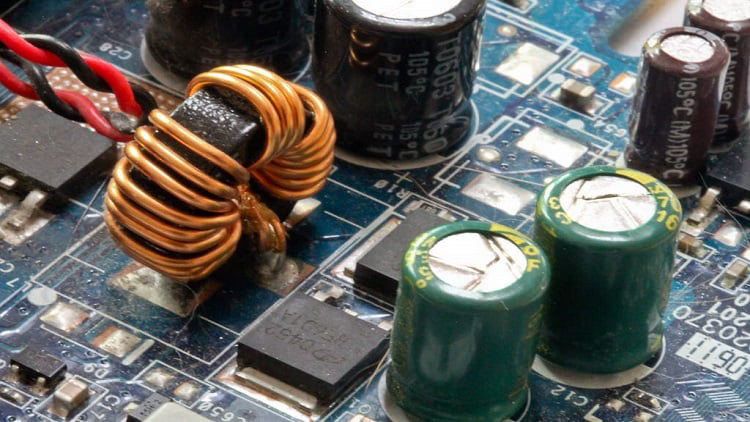

- Product development in EMI engineering (technical lead), R&D, EMI testing and certification (MIL-STD-461).

- Functional safety development (FMEDA, SFMEA) and certification (ISO26262).

- Reliability analysis & certification (MIL-HDBK-217, RIAC 217Plus).

- Requirements management & product development traceability (DOORS).

- Customer documentation delivery.

RENK Magnet Motor

RENK Magnet Motor

#3 Reducing "Electrosmog"

System- & Electric Engineering

Ensuring electro-magnetic compliance (EMC) for the Thales Hawkei (1.2B$) electric propulsion system.

EMC Compliance

Being able to measure EMC in-house for product development

Designing and Building an EMI Chamber from the Scratch to test prototypes before going to serial production, and improving their EMI design.

#4: Planting cells on Nanotechnology

Researcher

"A world of small things we cannot see with the naked eye."

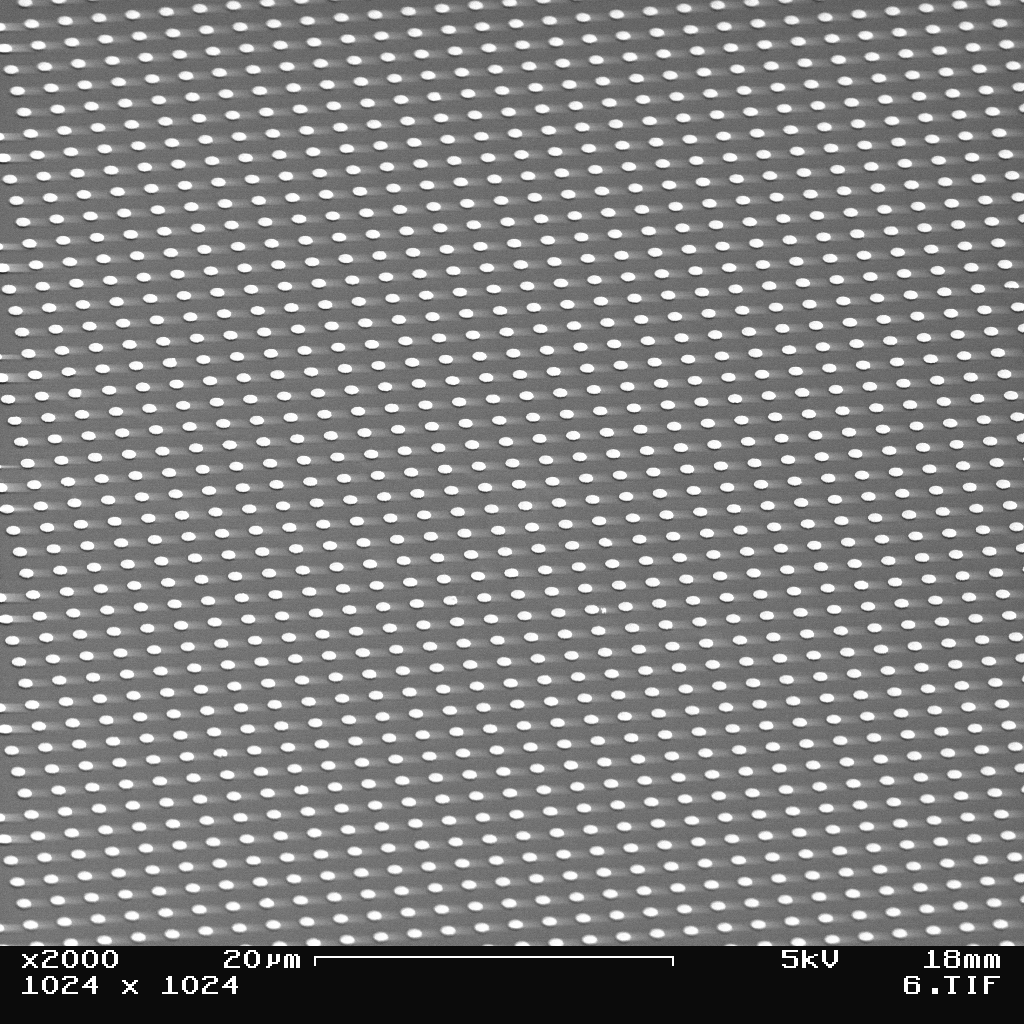

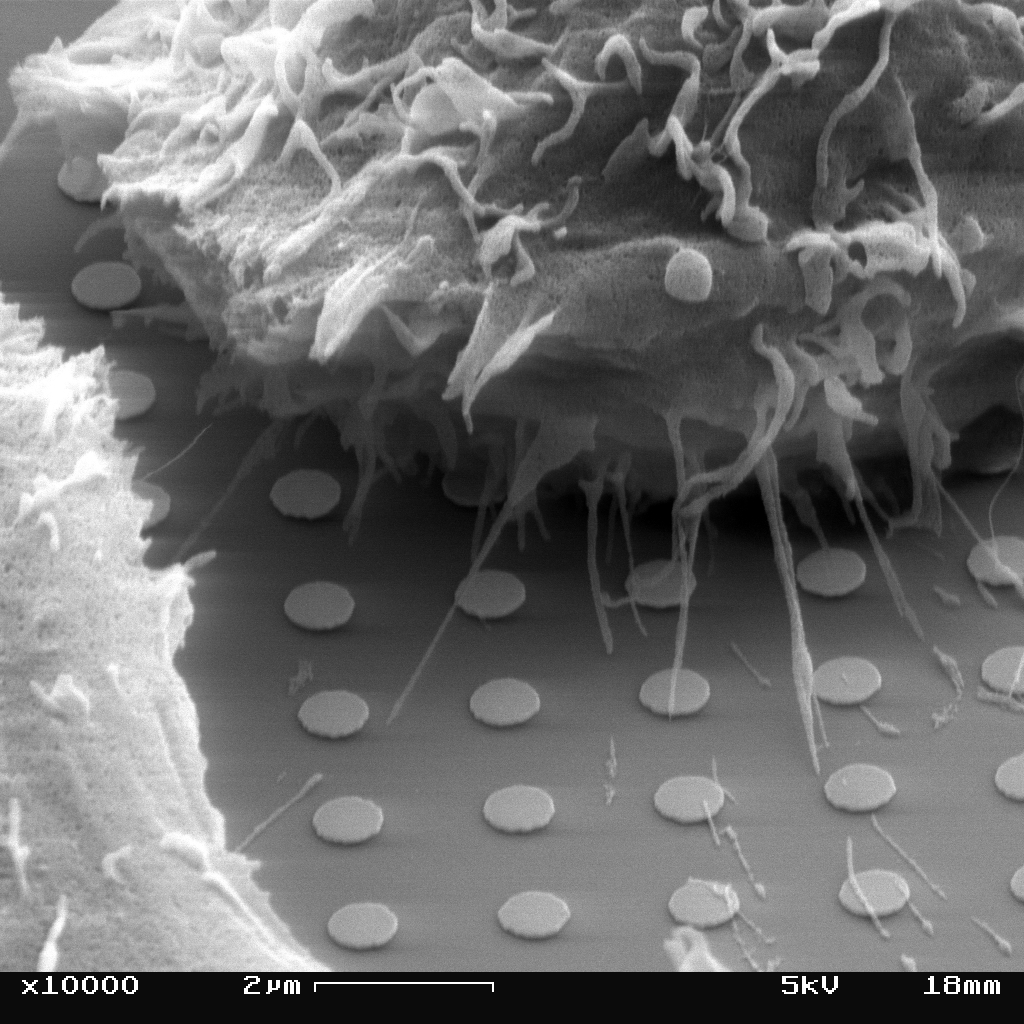

Analzying the optical effect of cells on nano structures

Challenge

Prooving a correlation between the Debye-Waller model in solid state physics and a perturbation model in biophysics to invent a new state of the art and lense-free (cost-efficient) microscopic method to measure cell activity and perform drug screening.

Results

The pertubation of Bragg Maxima were directly measurable by their light intensity and has been shown to be a correlation to the cell density (confluence level) on the nano structures.

These were groundbraking results that led to further experiments wich cells and bacteria, and finally to the formation of the startup Phio of my former colleague and supervisor Philipp Paulitschke.

"Interferometric detection of cell activity on periodic nano structures" (2014)

Approach

For a theoretical approach, the derivation of the nano structures under the cells were observed with a standard brightfield high resolution microscope, where the position of the nano tructures were tracked to observe the "lensing effect" of cells (picture). A549 human skin cancer cells were used for the experimencts.

The data of the pre-experiments showed a clear correlation between the cell activity and the structure displacement, which was translated by applying the Debye Waller model into the reciplrocal spce to measure the intensity of perturbation on the main Bragg-maxima.

For the experimental setup, a nanostructures were used to create a "Bragg-Sky" (picture) and measure the intensity of the 2nd main maxima. It took month to find the right components, while trying out several CCD camera sensors for future commercial use, instead using diodes in the end. In addition finding drifts in the laser-intensity wheel by potential material heating. A special probe chamber was built to maintain the cells at optimum temperature, to be able to grow them in the setup.

For the experimental procurement, A549 cells were cultivated on the chip (SiO2 & Gold), which went fine. During the measurements the cells were observed in an optical microscopie in sequence to check their health state opcically. Different confluence level were used to measure the correlation between to light intensity of the 2nd Bragg Maximum and so to proof the application of the Debye-Waller model on biological matter.

Interested?

status: open for work